Article Summary: Poor attic ventilation in South Florida traps extreme heat and moisture, causing shingles to fail early, decking to rot, mold to form, and energy bills to rise. Balanced intake and exhaust ventilation is essential to protect roof lifespan, warranties, HVAC efficiency, and indoor air quality—especially in coastal, hurricane-rated environments.

Key Takeaways:

• Ventilation failure destroys roofs fast: attic temps can exceed 150–165°F, accelerating shingle breakdown and often voiding manufacturer warranties.

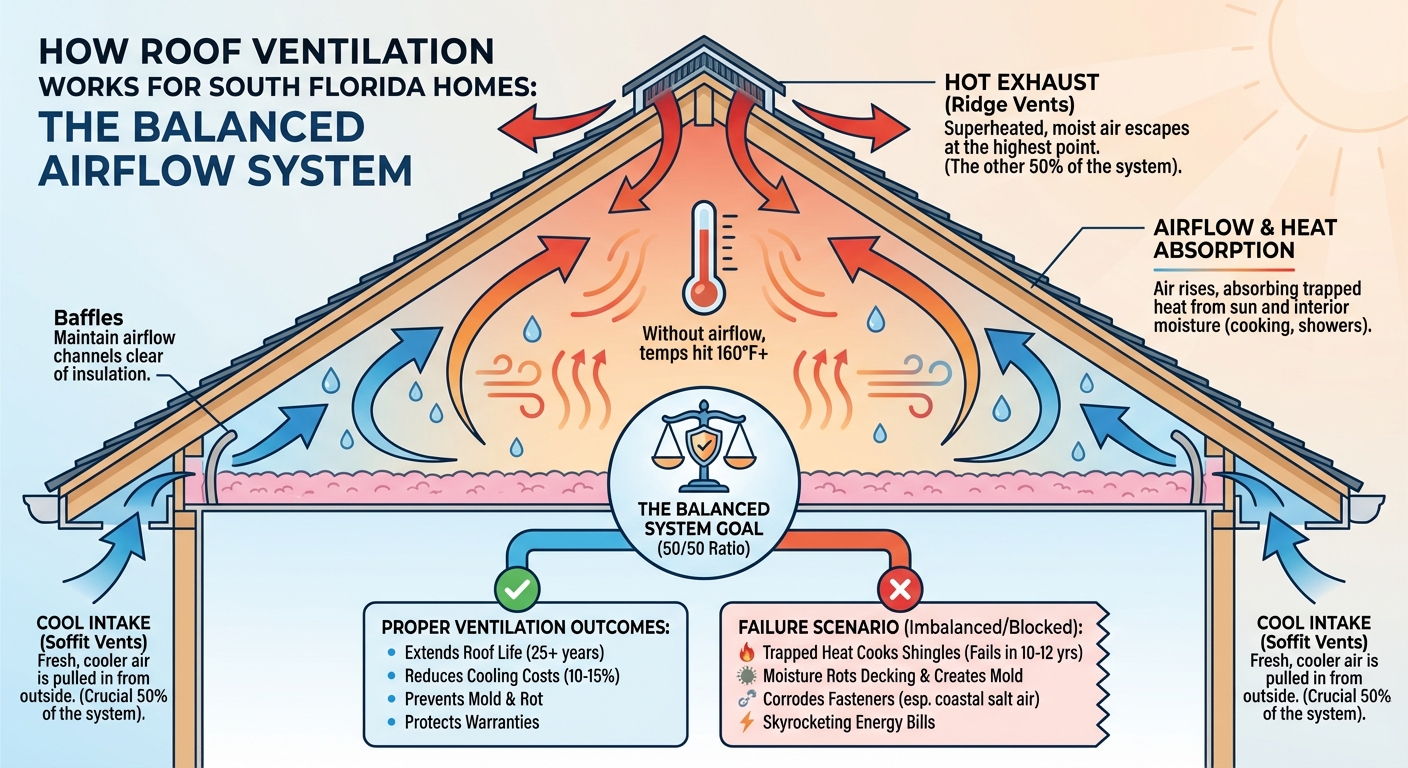

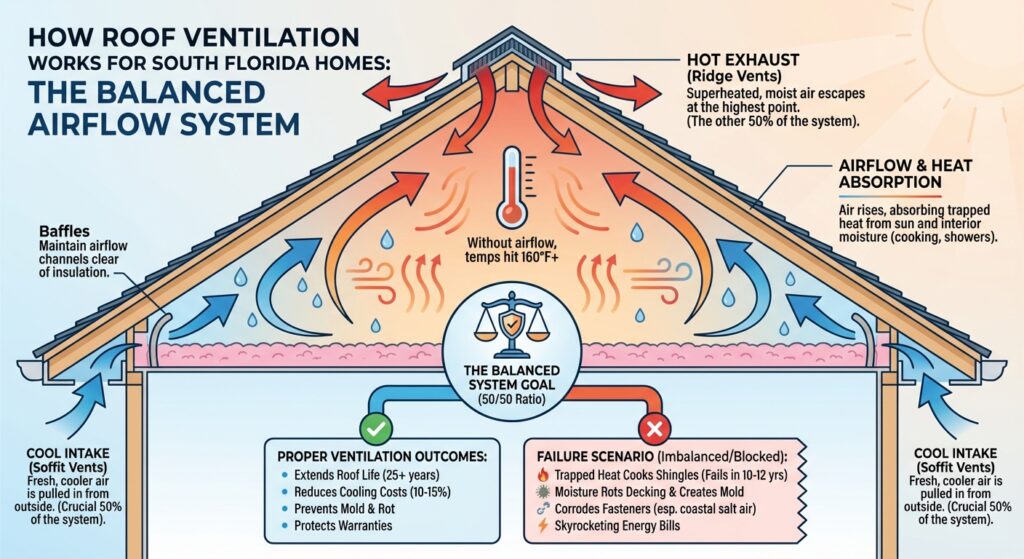

• Balanced airflow is non-negotiable: soffit intake + ridge/roof exhaust must be properly sized (often 50/50 split) to prevent heat/moisture dead zones

• Ventilation upgrades have high ROI: typically $600–$1,200, but can extend roof life 40–60%, reduce cooling costs ~10–15%, and prevent costly mold/decking repairs

Your attic needs to breathe, and in South Florida’s climate, failing to let it do so will cost you thousands in premature roof replacement, mold remediation, and skyrocketing energy bills. We’re not talking about marginal gains. We’re talking about the difference between a 15-year shingle roof and a 25-year one. The difference between comfortable indoor temperatures and a second-floor that feels like an oven by 2 PM.

At Bentley Roofing, we mandate balanced ventilation on every installation because we’ve replaced too many roofs that failed at year 12 when they should have lasted twice that long. The culprit wasn’t the shingles. It was trapped heat cooking them from below at 160°F while moisture rotted the decking. In Pompano Beach’s humid, salt-laden air, poor ventilation doesn’t just shorten roof life. It creates a cascading failure that impacts your HVAC system, your insulation, and your indoor air quality.

This breaks down when homeowners assume ventilation is optional or when contractors skip the intake-to-exhaust ratio calculations to save on labor. A roof without proper airflow isn’t protecting your home. It’s slowly destroying it.

How Ventilation Failure Destroys Roofs in Coastal Florida

When your attic temperature climbs above 150°F during summer months, which happens routinely in South Florida without adequate ventilation, the adhesive strips on asphalt shingles begin to soften. We’ve documented this on infrared assessments in Boca Raton homes where attic temps hit 165°F while outdoor air sat at 92°F. That 73-degree differential means your shingles are baking from both sides.

The result is premature granule loss, curling, and brittle cracking. Shingles rated for 25-year lifespans fail at 10 to 12 years. But here’s what most homeowners don’t realize: this damage voids most manufacturer warranties because inadequate ventilation is classified as improper installation.

Moisture compounds the problem. Florida’s humidity doesn’t just stay outside. It infiltrates your attic through daily activities like cooking, showering, and laundry. Without exhaust ventilation, that moisture condenses on roof decking when temperatures drop at night. We’ve torn off roofs in Fort Lauderdale where the OSB sheathing was black with mold despite no visible exterior leaks. The moisture came from inside, trapped by a ventilation system that consisted of two small gable vents for a 2,400-square-foot home.

In our coastal projects east of the Florida Turnpike, we also see accelerated fastener corrosion when ventilation fails. Trapped moisture combines with salt air infiltration to create an electrochemical nightmare. Galvanized nails rust through in 7 years instead of 20. This is why Bentley Roofing specifies 316 stainless steel fasteners for all coastal installations and refuses to compromise even when it adds $800 to the project cost.

The Physics of Balanced Airflow: Intake Equals Exhaust

Most ventilation failures we diagnose stem from imbalanced systems. Homeowners see ridge vents running the length of their roof peak and assume ventilation is adequate. They’re missing half the equation.

Ventilation requires two components working together: intake vents at the soffits to pull cool air in, and exhaust vents at the ridge or gable to release hot air. The ratio matters. Building codes in Broward and Palm Beach counties require 1 square foot of net free ventilation area per 150 square feet of attic space, with intake and exhaust balanced 50/50.

We routinely encounter homes where contractors installed continuous ridge vents but left soffits blocked by insulation or never cut soffit vents at all. The ridge vent can’t function without intake. Hot air has nowhere to pull from, so it stagnates. You’ve spent money on a ventilation system that does nothing.

The reverse scenario is equally problematic: homes with wide-open soffit vents but inadequate exhaust. Cool air enters but has no exit path, creating dead zones where heat accumulates at the roof peak. Both scenarios lead to the same outcome: thermal damage and moisture retention.

In our Pompano Beach installations, we calculate exact vent requirements before ordering materials. For a standard 2,000-square-foot ranch with 1,800 square feet of attic space, that means 12 square feet of net free area: 6 square feet of soffit intake and 6 square feet of ridge exhaust. We measure the effective area of each vent type, not just the physical opening, because screens and louvers reduce airflow by 50% or more.

What Proper Ventilation Actually Costs You (And What It Saves)

Adding or correcting ventilation during a roof replacement typically adds $600 to $1,200 to the project cost in South Florida. This includes cutting and installing continuous soffit vents if they’re missing, installing ridge vents along the full roof peak, and adding baffles to maintain airflow channels where insulation contacts the roof deck.

That upfront cost prevents three expensive failures:

First, it extends shingle life by 40% to 60%. A roof system that would otherwise fail at year 15 regularly reaches year 22 to 25 with proper ventilation. At current replacement costs of $18,000 to $28,000 for a typical South Florida home, you’re avoiding a premature re-roof that costs 20 times what the ventilation upgrade would have.

Second, it reduces cooling costs by 10% to 15% during summer months. When attic temperatures drop from 160°F to 120°F through active ventilation, the radiant heat load on your ceiling insulation decreases substantially. Your HVAC system doesn’t have to fight a 160-degree heat source pressing down from above. We’ve tracked energy bills for clients in our Preferred Protection Plan, and homes with corrected ventilation average $35 to $55 in monthly savings from June through September.

Third, it prevents moisture damage that requires $4,000 to $12,000 in mold remediation and decking replacement. Once mold colonizes your attic or roof decking delaminates from moisture saturation, you’re facing structural repairs that insurance often won’t cover because they classify it as maintenance-related deterioration rather than sudden loss.

At Bentley Roofing, we’ve walked away from projects where homeowners demanded we skip ventilation upgrades to meet a competitor’s lower bid. We will not install a roof system designed to fail. The savings aren’t worth the liability, and more importantly, it’s not what a certified contractor should do to a client’s home.

Red Flags: How to Spot Ventilation Problems Before Catastrophic Failure

You don’t need to climb into your attic with a thermometer to identify ventilation issues, though that’s the definitive test. Watch for these indicators:

Your second-floor bedrooms stay 5 to 8 degrees warmer than the first floor even when the AC runs continuously. This temperature stratification signals heat radiating down through inadequately ventilated attic space.

Shingles show curling, cupping, or wavy patterns before reaching half their rated lifespan. Thermal cycling from trapped attic heat causes this distortion. If your 7-year-old roof looks like it’s 15 years old, ventilation failure is the likely cause.

You see dark streaking or discoloration on interior ceiling paint near exterior walls. This often indicates condensation forming where warm attic air meets cooler ceiling surfaces, a moisture problem ventilation should prevent.

Your energy bills climbed 20% or more over three summers despite no rate increases or usage changes. Progressive ventilation blockage, often from insulation settling over soffit vents, reduces airflow gradually.

Ice dams form during the rare South Florida cold snap. Yes, we occasionally see this in Pompano Beach when temperatures drop to the high 30s overnight. Poor ventilation allows attic heat to melt frost on the roof surface unevenly, creating ice at the eaves.

During our 17-point roof inspections, we check attic temperatures, measure ventilation area, verify soffit clearance, and use moisture meters on decking. These issues don’t fix themselves. They compound until something fails catastrophically, usually triggering an insurance claim that discovers the underlying ventilation deficiency and denies coverage.

Ventilation Requirements for South Florida’s Specific Challenges

Coastal humidity creates ventilation demands that differ from the rest of the country. The reference materials cite general standards, but in Broward and Palm Beach counties, we’re operating in a High Velocity Hurricane Zone where building codes layer additional requirements.

Every roof penetration, including ventilation components, must meet Miami-Dade County Product Control approval for wind resistance. This means ridge vents rated for 150+ mph winds and soffit vents that won’t pull off during storm surge. Generic big-box ridge vents fail these standards. We specify products like Owens Corning VentSure ridge vents that carry the Miami-Dade NOA (Notice of Acceptance) because they’ve passed the Large Missile Impact Test.

Salt air infiltration also requires material selection beyond standard practice. Aluminum soffit vents corrode within 5 years in Lighthouse Point and Deerfield Beach. We install powder-coated stainless or high-grade vinyl soffit vents that resist electrochemical breakdown. The cost difference is $150 for a typical home, but it prevents vent failure that blocks intake airflow.

Flat and low-slope roofs, common in South Florida commercial buildings and some contemporary residential designs, require different ventilation approaches. You can’t install ridge vents on a flat TPO roof. Instead, we use turbine vents, powered attic fans, or through-roof mushroom vents positioned to create cross-ventilation. These systems need more aggressive exhaust because thermal convection doesn’t assist airflow the way it does on steep-slope roofs.

Tile roofing, popular in Boca Raton and upscale Pompano Beach neighborhoods, integrates ventilation differently. The barrel or S-curve profile of concrete and clay tiles creates natural air channels under the tile layer. But this only works if you have proper soffit intake and ridge exhaust. We see tile roofs where contractors assumed the tile profile provided ventilation and skipped the soffit vents entirely. It doesn’t work that way. You still need balanced intake and exhaust, or the tile installation becomes an expensive decorative layer over a failing roof deck.

When This Advice Does Not Apply

Proper ventilation is critical for standard attic spaces, but certain roof configurations and building types operate under different rules:

Cathedral ceilings with no attic space require ventilation channels between the roof deck and insulation rather than traditional attic ventilation. These systems use continuous soffit-to-ridge baffles, and adding standard attic vents would accomplish nothing.

Spray foam insulation applied directly to the underside of the roof deck creates an unvented attic system. This approach intentionally seals the attic as conditioned space, moving it inside the building envelope. Adding ventilation to a spray-foamed attic destroys the thermal boundary and causes moisture problems. If your attic has spray foam insulation, do not add vents without consulting a building science professional.

Flat commercial roofs with parapet walls often use fully adhered membrane systems where the insulation and waterproofing create an unvented assembly. These roofs manage moisture through vapor barriers and insulation placement rather than airflow.

Historic homes with existing plaster ceilings and unique roof framing may not accommodate modern ventilation without compromising structural or historic integrity. These require custom solutions beyond standard vent installation.

If you’re unsure whether your home falls into one of these categories, the safe approach is a professional assessment before modifying ventilation. At Bentley Roofing, we won’t install vents on a spray-foamed attic or cut soffit openings in a cathedral ceiling system. The building science has to match the strategy, or you create worse problems than you solve.

Why Bentley Roofing Treats Ventilation as Non-Negotiable

We’ve replaced roofs that failed at year 11 because the original contractor saved 4 hours of labor by skipping soffit vent installation. The homeowner paid $22,000 for a roof system that should have lasted 25 years but didn’t make it to 12. When we tore it off, the decking was warped, three rafters showed mold growth, and the ridge board had separated from thermal expansion cycles.

That’s why every Bentley Roofing installation includes calculated ventilation as part of the base scope. We don’t offer it as an upgrade or optional add-on. It’s engineered into the system because a roof without proper ventilation isn’t a complete roof. It’s a liability waiting for a triggering event.

Our approach: measure the attic square footage, calculate required net free area per Florida Building Code, verify soffit access, install baffles to maintain insulation clearance, and install continuous ridge vents with appropriate intake. For coastal projects, we upgrade to stainless fasteners and corrosion-resistant vent materials. For tile roofs, we ensure the base ventilation system works independently of the tile layer.

If your current roof shows signs of ventilation failure or you’re planning a replacement, contact us to schedule a comprehensive roof inspection. We’ll assess your existing ventilation, measure attic temperatures, check for moisture damage, and provide a detailed scope of what’s required to protect your investment for the next 20-plus years. The upfront cost of doing it correctly is always less than the cost of doing it twice.